Industrial Louvers for Factories & Warehouses | Complete Buyer Guide

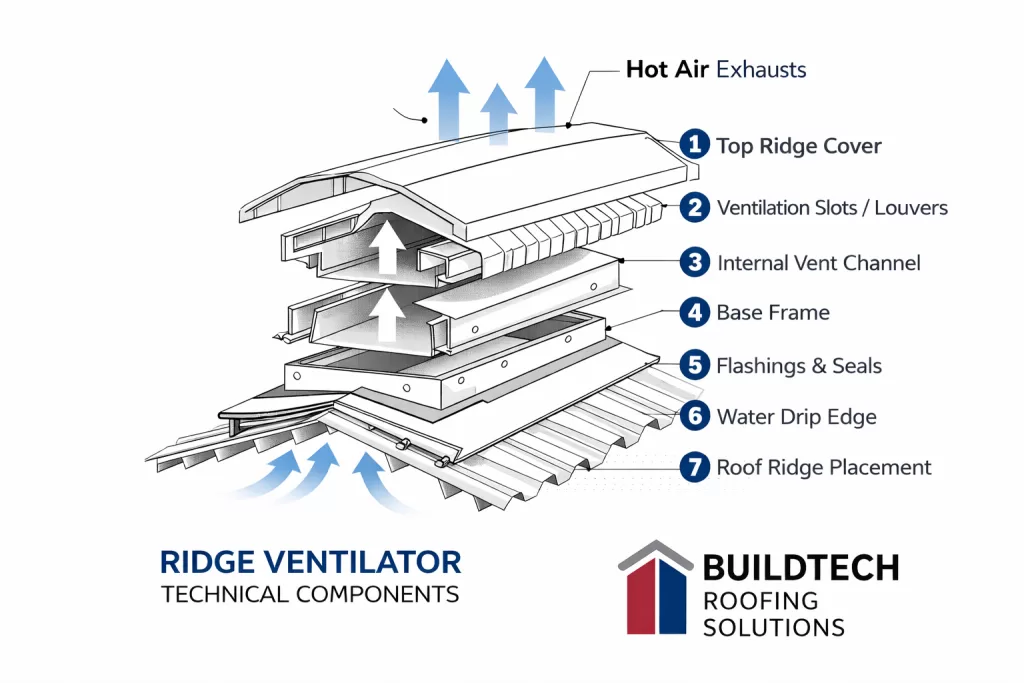

Introduction: Why Industrial Louvers Matter in Modern Industrial Buildings Ventilation is a foundational requirement in industrial and commercial building design. Facilities such as factories, warehouses, manufacturing units, and power plants continuously generate heat, dust, fumes, and moisture. If these elements are not managed effectively, they can affect worker safety, reduce equipment lifespan, and increase operational costs. While roof-based ventilation systems like ridge ventilators and turbo ventilators help release hot air, they cannot function efficiently without a controlled air intake system. This is where industrial louvers become essential. Industrial louvers regulate how fresh air enters and exits a building while protecting interiors from rain, dust, birds, and external contaminants. When designed and installed correctly, they form a critical part of a balanced, energy-efficient ventilation system. This comprehensive buyer’s guide explains industrial louvers in detail, covering their function, types, materials, applications, technical specifications, and selection guidelines for long-term performance. What Are Industrial Louvers? Industrial louvers are engineered airflow management systems installed on building walls, facades, or ventilation openings. They allow controlled air movement while restricting unwanted elements such as rainwater, debris, insects, and birds from entering the structure. Unlike open windows or unprotected vents, louvers use angled blades or fins that direct airflow efficiently and safely. This design ensures ventilation without compromising protection. How Industrial Louvers Work Industrial louvers operate on a passive airflow principle: When paired with ridge ventilators or turbo ventilators, louvers help establish a stable air circulation cycle, enhancing natural ventilation throughout the building. Why Industrial Louvers Are Critical for Industrial Environments Industrial facilities require controlled airflow rather than exposed openings. Louvers deliver this control by managing intake and exhaust in a predictable manner. Without proper louver systems, buildings often face: Industrial louvers address these challenges while improving indoor comfort and safety. Key Benefits of Industrial Louvers 1. Controlled Airflow Louvers regulate air volume, preventing pressure imbalance and sudden airflow changes inside the building. 2. Weather Protection Special blade geometry blocks rainwater even during heavy rainfall or strong winds. 3. Dust and Debris Reduction Industrial designs minimize dust, sand, and external particle entry. 4. Improved Indoor Air Quality Fresh air circulation reduces heat, humidity, and airborne contaminants. 5. Low Maintenance Requirements With no moving parts, industrial louvers require minimal upkeep. 6. Seamless Integration with Ventilation Systems Louvers complement natural and mechanical ventilation solutions effectively. Types of Industrial Louvers 1. Fixed Industrial Louvers These louvers have non-movable blades and are widely used for general ventilation. Key Features: Applications: Warehouses, factories, utility areas 2. Z-Type Industrial Louvers Z-shaped blades enhance rain protection and airflow control. Key Features: Applications: Manufacturing units, electrical rooms 3. Rain-Proof Industrial Louvers Designed for regions with high rainfall intensity. Key Features: Applications: Coastal and high-rainfall zones 4. Sand Trap Louvers Engineered for dusty and sandy environments. Key Features: Applications: Cement plants, mining facilities 5. Bird-Proof Louvers Equipped with bird mesh or integrated protection. Key Features: Applications: Food processing units, warehouses Materials Used in Industrial Louvers Material selection directly affects durability, corrosion resistance, and lifecycle cost. Common Materials Importance of Material Selection Technical Specifications of Industrial Louvers (Typical Range) Parameter Specification Material GI / PPGI / Aluminium Thickness 0.50 – 1.00 mm Blade Type Fixed / Z-Type Finish Plain / Colour-Coated Installation Wall-mounted Maintenance Minimal Applications of Industrial Louvers Industrial louvers are widely used across multiple sectors, including: They are particularly important where fresh air intake and environmental protection must function together. Industrial Louvers vs Open Windows Aspect Industrial Louvers Open Windows Airflow Control Controlled Uncontrolled Weather Protection High Low Dust Resistance High Low Industrial Suitability Ideal Not recommended Maintenance Low Moderate Design Considerations When Choosing Industrial Louvers Airflow Requirement Determine airflow volume based on building size, heat load, and ventilation strategy. Environmental Conditions Dusty, coastal, or high-rainfall regions require specialized louver designs. Installation Location Wall orientation impacts airflow efficiency and weather exposure. Integration with Ventilation Systems Louvers should complement ridge or turbo ventilators for optimal performance. Installation Process Overview Proper installation ensures durability and performance. Typical Steps Include: Correct sealing prevents leakage, vibration, and long-term issues. Common Buyer Mistakes to Avoid Avoiding these mistakes significantly reduces future maintenance costs. Energy Efficiency and Sustainability Benefits Industrial louvers contribute to sustainable building practices by: They support energy-efficient and eco-conscious industrial infrastructure. Why Choose Buildtech Roofing Solutions Buildtech Roofing Solutions delivers complete industrial louver systems designed for performance and longevity. Our Strengths Include: We focus on durability, efficiency, and long-term value. Frequently Asked Questions (FAQ) Q1. Are industrial louvers waterproof?Yes. Rain-proof designs effectively prevent water ingress. Q2. Do louvers help reduce heat inside buildings?Yes. They improve airflow and support roof ventilation systems. Q3. How much maintenance do industrial louvers require?Minimal maintenance is needed due to their fixed design. Q4. Can industrial louvers be customized?Yes. Size, material, thickness, and finish can be customized. Conclusion Industrial louvers are a critical component of efficient industrial ventilation systems. They provide controlled airflow, protect interiors from environmental elements, and enhance indoor air quality. Selecting the right industrial louver system improves worker comfort, safeguards equipment, and reduces operational costs over time. When integrated with a well-designed ventilation strategy, industrial louvers deliver lasting performance and energy efficiency. Final Call to Action 📞 Call: 9158340909📩 Request a Professional Industrial Louver Consultation Today

Industrial Louvers for Factories & Warehouses | Complete Buyer Guide Read More »