Industrial Roofing Project Timeline Guide: From Inspection to Completion

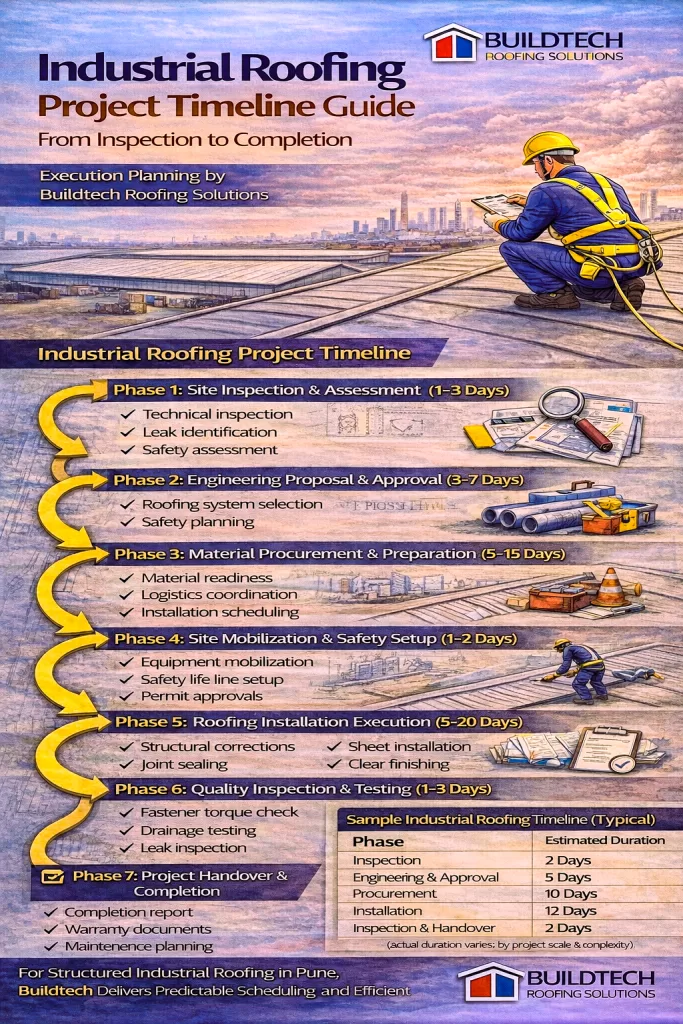

Introduction: Why Industrial Roofing Project Timeline Planning Matters Before starting any roofing work, factory owners and facility managers ask practical questions: An industrial roofing project timeline is not just a schedule—it is a structured execution roadmap. Industrial roofing must be coordinated within an operating facility, where safety, production continuity, and logistics matter. A clearly defined industrial roofing project timeline allows factories and warehouses in Pune to reduce downtime, allocate resources effectively, and ensure predictable execution. This guide explains each phase, expected duration, and how professional planning ensures smooth completion. Overview of an Industrial Roofing Project Timeline A professional industrial roofing project timeline follows structured phases: Each stage builds on the previous one to prevent delays and rework. Phase 1: Site Inspection & Technical Assessment (1–3 Days) Every industrial roofing project timeline begins with a technical inspection. Key Activities Outcome A technically accurate proposal and realistic project schedule. Proper inspection prevents underestimation, which is one of the most common causes of project delay. Phase 2: Engineering Proposal & Approval (3–7 Days) After inspection, engineering planning defines the next stage of the industrial roofing project timeline. Includes: Coordination with facility management ensures minimal operational disruption. Phase 3: Material Procurement & Preparation (5–15 Days) Material readiness significantly impacts the industrial roofing project timeline. Key Factors Experienced contractors align procurement schedules with installation start dates to prevent idle time. Phase 4: Site Mobilization & Safety Setup (1–2 Days) Before installation begins, structured mobilization takes place. Preparation Tasks A strong safety setup prevents interruptions and compliance issues. Phase 5: Roofing Installation Execution (5–20 Days) This is the core stage of the industrial roofing project timeline. Duration Depends On: Typical Workflow Professional teams divide work into zones to allow factories to continue operations during installation. Phase 6: Quality Inspection & Testing (1–3 Days) Before completion, verification ensures performance standards are met. Quality Checks Include: Quality control protects long-term durability and reduces future repair risk. Phase 7: Project Handover & Documentation (1 Day) The final stage of the industrial roofing project timeline includes formal documentation. Deliverables: Documentation ensures transparency and accountability. Factors That Influence an Industrial Roofing Project Timeline Several variables may extend or compress timelines: Realistic scheduling accounts for these variables early in planning. Sample Industrial Roofing Project Timeline (Illustrative) Phase Estimated Duration Inspection 2 Days Engineering & Approval 5 Days Procurement 10 Days Installation 12 Days Inspection & Handover 2 Days Total Estimated Timeline: 3–4 Weeks(Actual duration varies by project scale and complexity.) How to Prepare Your Factory Before Roofing Work Preparation shortens the industrial roofing project timeline. Recommended actions: Preparation prevents avoidable delays. Can Roofing Continue Without Stopping Production? In most industrial facilities, yes. Professional contractors plan: A properly structured industrial roofing project timeline allows continued operations in many cases. How Professional Contractors Reduce Timeline Risk Experienced contractors maintain schedule stability through: Planning efficiency is often more critical than workforce size. Why Industries Choose Buildtech Roofing Solutions Buildtech Roofing Solutions follows a structured execution methodology: This system ensures predictable industrial roofing project timelines and minimal operational disruption for factories in Pune. FAQs: Industrial Roofing Project Timeline How long does an industrial roofing project timeline typically last?Most projects range between 2–4 weeks, depending on size and complexity. Can roofing work be done without stopping production?Yes, phased execution often allows operations to continue safely. What causes delays in an industrial roofing project timeline?Weather, structural corrections, and material lead times are common factors. Why is inspection essential before scheduling?Inspection identifies structural risks and ensures accurate timeline planning. Conclusion: A Structured Industrial Roofing Project Timeline Ensures Predictable Results A clearly defined industrial roofing project timeline transforms complex roofing execution into a controlled and manageable process. Inspection, engineering planning, procurement coordination, safety integration, and professional supervision collectively ensure projects finish efficiently and reliably. For structured industrial roofing project timeline planning and professional execution in Pune, Buildtech Roofing Solutions delivers dependable scheduling and minimal disruption to operations.

Industrial Roofing Project Timeline Guide: From Inspection to Completion Read More »