Introduction: Why Most Industrial Roof Failures Are Preventable

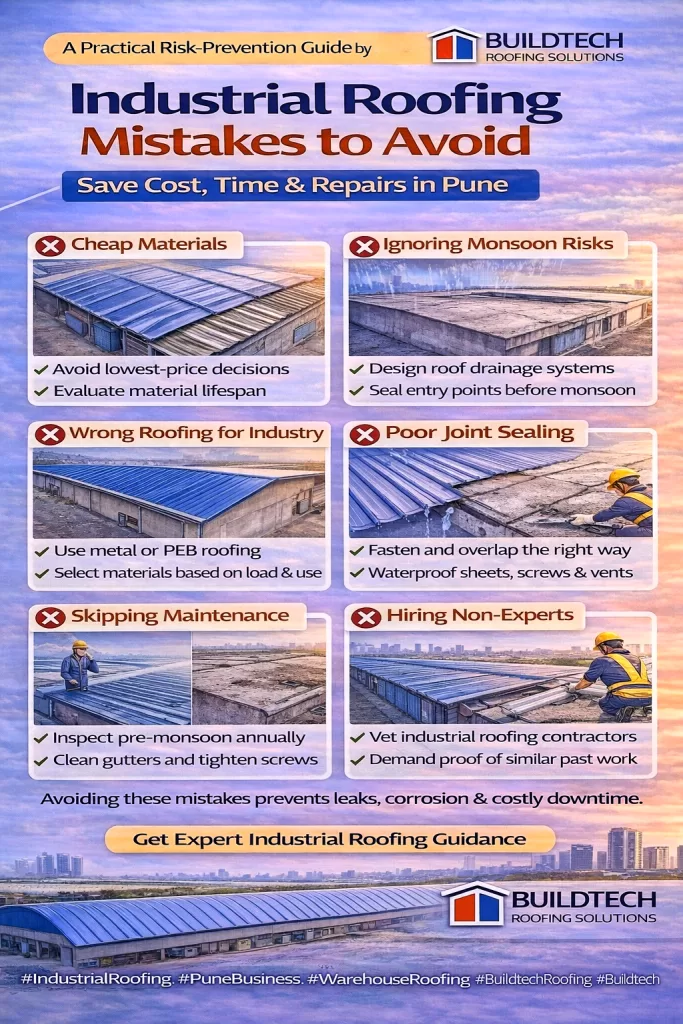

In Pune’s industrial zones, roofing failures are rarely sudden accidents. In most cases, they are the result of avoidable mistakes—wrong material selection, poor installation practices, ignored waterproofing, or lack of maintenance. These mistakes become painfully visible during monsoon season, when minor defects turn into leaks, corrosion, and operational shutdowns.

This guide highlights the most common industrial roofing mistakes seen in factories, warehouses, and industrial sheds across Pune—and explains the correct practices that prevent long-term damage, repeated repairs, and unnecessary expenditure.

❌ Mistake #1: Choosing Roofing Based Only on Lowest Price

What Goes Wrong

- Thin or low-grade roofing sheets

- Inferior fasteners and sealants

- No allowance for waterproofing or ventilation

Low-cost roofing often looks economical on day one, but becomes the most expensive option over time.

Correct Practice

- Evaluate lifecycle cost, not just initial price

- Compare material lifespan, maintenance, and downtime impact

A slightly higher upfront investment often saves lakhs in future repairs.

❌ Mistake #2: Ignoring Pune’s Monsoon Conditions in Roofing Design

What Goes Wrong

- Insufficient roof slope

- Poorly designed gutters and downpipes

- Water ponding near joints and ridges

During heavy rainfall, these design flaws cause leakage and accelerated corrosion.

Correct Practice

- Engineer the roof slope for fast water runoff

- Design adequate drainage capacity

- Treat joints and penetrations as critical zones

Monsoon-ready design is non-negotiable in Pune.

❌ Mistake #3: Selecting the Wrong Roofing Material for Industrial Use

Common Errors

- RCC concrete slabs for large-span sheds

- Legacy asbestos sheets are still in use

- Lightweight sheets not designed for wind load

These materials struggle with span, weight, and long-term durability.

Correct Practice

- Use metal roofing or PEB roofing systems for most industrial applications

- Choose materials based on span, load, and operational use—not habit

Correct material choice determines roof performance for decades.

❌ Mistake #4: No Planning for Ventilation and Daylighting

Consequences

- Excessive heat buildup inside sheds

- Reduced worker comfort and productivity

- Higher energy bills due to artificial lighting and cooling

Many industrial roofs fail to address the internal environment needs.

Correct Practice

- Integrate ridge ventilators or turbo ventilators

- Plan skylights for natural daylight without heat gain

Ventilation and daylighting are functional requirements, not optional extras.

❌ Mistake #5: Poor Fastener and Joint Installation

What Goes Wrong

- Incorrect fastener spacing

- Low-quality screws without sealing washers

- Improper overlap alignment

Most industrial roof leaks originate from joints and fasteners, not the sheets themselves.

Correct Practice

- Use industrial-grade fasteners and washers

- Follow engineered fixing patterns

- Seal joints professionally during installation

Precision at joints prevents years of leakage issues.

❌ Mistake #6: Treating Waterproofing as Optional

Reality Check

Even the best roofing material will fail without proper waterproofing at:

- Sheet overlaps

- Fasteners

- Skylights, vents, and penetrations

Skipping waterproofing is one of the costliest mistakes.

Correct Practice

- Integrate waterproofing during design and installation

- Reinforce vulnerable zones with liquid membranes or sealants

Waterproofing should be proactive, not reactive.

❌ Mistake #7: Skipping Preventive Roofing Maintenance

What Happens

- Small defects go unnoticed

- Corrosion spreads

- Emergency repairs during the monsoon

Most emergency roof failures could have been avoided with basic inspections.

Correct Practice

- Conduct pre-monsoon inspections every year

- Clean drainage systems

- Tighten fasteners and touch up coatings

Preventive maintenance costs a fraction of emergency repairs.

❌ Mistake #8: Hiring Non-Specialized Roofing Contractors

Risks

- No engineering assessment

- Improvised installation methods

- Lack of documentation and accountability

General contractors often lack industrial roofing expertise.

Correct Practice

- Choose contractors with industrial roofing experience

- Ensure they provide inspection reports and specifications

- Look for long-term maintenance capability

Industrial roofing requires specialization, not shortcuts.

❌ Mistake #9: No Repair vs Replacement Assessment

Common Error

- Full roof replacement when targeted repair would suffice

- Or repeated patchwork when replacement is actually required

Both approaches waste money when not properly assessed.

Correct Practice

- Conduct a professional roof condition audit

- Decide on repair or replacement based on structural health and lifecycle cost

The right diagnosis saves both time and capital.

❌ Mistake #10: No Proof of Past Industrial Projects

Why This Is Risky

- Claims without evidence

- No understanding of industrial challenges

- Higher execution risk

Correct Practice

- Review real industrial case studies

- Check project scale, complexity, and outcomes

Past performance is the best predictor of future reliability.

Summary Table: Common Mistakes vs Correct Practices

| Common Mistake | Correct Practice |

|---|---|

| Lowest-price selection | Lifecycle ROI analysis |

| No waterproofing | Integrated sealing |

| Poor drainage | Engineered slope & gutters |

| No ventilation | Planned airflow systems |

| No maintenance | Preventive inspection plan |

| Wrong contractor | Industrial roofing specialist |

Expert Recommendation from Buildtech Roofing Solutions

Industrial roofing should be treated as critical infrastructure, not a commodity. Most failures are the result of decisions made at the design or installation stage—not material defects. An engineering-led approach eliminates the majority of risks before the first sheet is installed.

FAQs: Industrial Roofing Mistakes

What is the most common industrial roofing mistake?

Choosing roofing based only on the lowest price without considering lifecycle cost.

Can roofing mistakes be corrected after installation?

Many can be mitigated through repair and waterproofing, but prevention is always cheaper.

How can I audit my existing industrial roof?

A professional inspection covering joints, fasteners, drainage, and waterproofing is the best starting point.

Conclusion: Avoid Mistakes Early, Save for Years

Avoiding these industrial roofing mistakes can save factories and warehouses in Pune from repeated leakage, downtime, and escalating costs. The right decisions—made early—deliver durable, safe, and low-maintenance roofing systems that perform reliably through every monsoon.

For expert assessment and mistake-free industrial roofing solutions, Buildtech Roofing Solutions provides engineering-driven guidance and execution across Pune and Maharashtra.