Introduction: Why Roofing Material Choice Decides Long-Term Performance

For industrial buildings, the roof is not a cosmetic element—it is a mission-critical system. The wrong material can lead to leakage, overheating, corrosion, frequent repairs, and operational downtime. Pune’s climate—heavy monsoon rainfall, high summer temperatures, and industrial pollution—makes material selection the single most important roofing decision.

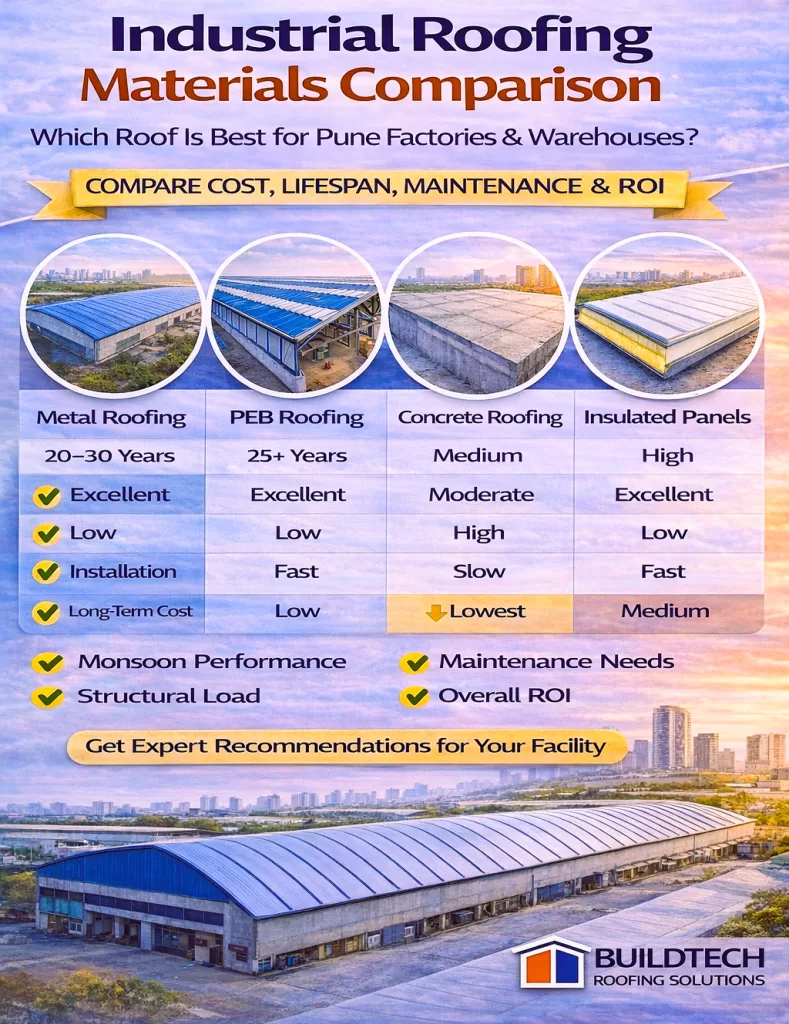

This industrial roofing materials comparison explains how common options perform in real factory and warehouse conditions. You’ll see clear differences in lifespan, monsoon behaviour, maintenance needs, and long-term cost—so you can choose based on performance and ROI, not just initial price.

Section 1: Common Industrial Roofing Materials Explained

1) Metal Roofing Sheets (Most Widely Used)

Metal roofing uses color-coated or galvanized steel sheets engineered for strength and weather resistance.

Strengths

- Excellent monsoon performance

- Lightweight with a high strength-to-weight ratio

- Fast installation and easy upgrades

- Low maintenance over 20–30 years

Considerations

- Correct thickness and fastening are critical

- Joints and penetrations must be sealed professionally

Best for: Manufacturing units, warehouses, logistics hubs, retrofits.

2) PEB Shed Roofing Systems

PEB (Pre-Engineered Building) roofing integrates engineered steel frames with optimized metal roofing for large clear spans.

Strengths

- Long spans with fewer columns

- Precision engineering and faster timelines

- Excellent drainage, ventilation, and daylight integration

- Lowest lifecycle cost for large facilities

Considerations

- Requires engineering-led design and execution

- Best planned at project inception (new builds or major expansions)

Best for: Warehouses, logistics parks, large factories.

3) Concrete (RCC) Roofing

Reinforced concrete slabs are traditionally used in some industrial and commercial buildings.

Strengths

- High compressive strength

- Familiar construction method

Limitations

- Heavy load on the structure

- Prone to cracks and seepage over time

- Higher maintenance and waterproofing dependency

- Slower construction

Best for: Multi-storey structures where slab floors are required (not ideal for large sheds).

4) Insulated Roofing Panels (PUF / Sandwich Panels)

Factory-made panels with insulation cores between metal skins.

Strengths

- Excellent thermal and acoustic insulation

- Stable indoor temperatures

- Clean installation and low maintenance

Considerations

- Higher upfront cost

- Best ROI where temperature control matters

Best for: Cold storage, pharma, food processing, electronics.

5) Legacy Asbestos Roofing (Being Replaced)

Older industrial buildings may still have asbestos sheets.

Limitations

- Short lifespan and brittle behaviour

- Poor monsoon performance

- Health and safety concerns

- High long-term cost due to frequent failures

Best practice: Replace with metal or PEB roofing.

Section 2: Industrial Roofing Materials Comparison Table (Core Decision View)

| Parameter | Metal Roofing | PEB Roofing | Concrete (RCC) | Insulated Panels |

|---|---|---|---|---|

| Lifespan | High (20–30 yrs) | Very High (25+ yrs) | Medium | High |

| Monsoon Performance | Excellent | Excellent | Moderate | Excellent |

| Heat Control | Good | Good | Poor | Excellent |

| Maintenance | Low | Low | High | Low |

| Installation Speed | Fast | Very Fast | Slow | Fast |

| Structural Load | Low | Optimized | Very High | Low |

| Long-Term Cost | Low | Lowest | High | Medium |

Takeaway: For most Pune industries, metal or PEB roofing delivers the best balance of performance and ROI.

Section 3: Best Roofing Material by Industrial Use-Case

Manufacturing Units

- Recommended: Metal or PEB roofing

- Why: Strength, ventilation, fast repairs, low downtime

Warehouses & Logistics

- Recommended: PEB roofing with skylights

- Why: Large spans, daylighting, lowest lifecycle cost

Cold Storage, Pharma, Food Processing

- Recommended: Insulated panels

- Why: Temperature stability and hygiene

Older Industrial Buildings (Retrofit)

- Recommended: Metal roofing overlay + waterproofing

- Why: Quick upgrade without structural overload

Section 4: Monsoon Performance Comparison (Pune Focus)

Metal / PEB Roofing

- High water-shedding capability

- Engineered slopes and gutters

- Joint sealing prevents seepage

Concrete Roofing

- Crack formation leads to seepage

- Heavy reliance on waterproofing layers

- Frequent maintenance during the monsoon

Insulated Panels

- Excellent sealing and joint systems

- Minimal leakage when installed correctly

Verdict: Monsoon resilience favours metal-based systems with professional detailing.

Section 5: Maintenance & Repair Perspective

- Lowest maintenance: PEB and insulated panels

- Moderate maintenance: Metal roofing (periodic fastener checks)

- Highest maintenance: Concrete roofs (cracks, waterproofing cycles)

A roof that is easy to maintain reduces annual costs and avoids emergency shutdowns.

Section 6: Cost vs Lifecycle ROI (Buyer Decision Section)

Initial cost can mislead.

When evaluated over 20 years:

- PEB roofing often delivers the lowest total cost of ownership

- Metal roofing offers excellent ROI with flexibility for upgrades

- Concrete roofing appears durable, but it incurs higher maintenance and repair costs

- Insulated panels justify cost where energy savings are critical

Rule of thumb: Choose based on lifecycle ROI, not the lowest quotation.

Section 7: Common Buyer Mistakes When Choosing Roofing Materials

- Selecting the cheapest option without lifecycle analysis

- Ignoring waterproofing compatibility with the material

- Not planning ventilation and daylighting

- Overloading structures with heavy roofing

- No preventive maintenance strategy

Avoiding these mistakes can save years of repairs and lost productivity.

Section 8: Expert Recommendations (Practical Guidance)

- Choose metal roofing for flexibility, durability, and quick execution

- Choose PEB roofing for large spans and long-term cost efficiency

- Choose insulated panels only where temperature control is essential

- Avoid asbestos and under-designed concrete roofs for industrial sheds

A site-specific assessment ensures the right balance of cost, performance, and lifespan.

Section 9: FAQs (Snippet-Ready)

Which industrial roofing material lasts the longest?

PEB roofing systems typically offer the longest service life with the lowest lifecycle cost.

Is metal roofing better than concrete for factories?

Yes. Metal roofing is lighter, faster to install, easier to maintain, and more monsoon-resilient.

What roofing is best for Pune monsoon conditions?

Engineered metal or PEB roofing with proper drainage and sealing.

Which roofing option needs the least maintenance?

PEB roofing and insulated panels, when installed correctly.

Conclusion: Choose Materials That Protect Operations—not Just Buildings

This industrial roofing materials comparison shows that the best roofing choice is the one that protects operations, reduces downtime, and minimizes long-term cost. For most Pune factories and warehouses, metal or PEB roofing delivers the strongest combination of durability, monsoon performance, and ROI.

For material selection based on real site conditions, Buildtech Roofing Solutions provides engineering-led guidance that helps industries invest once—and perform for decades.