Introduction: Why an Industrial Roofing Inspection Checklist Matters

Industrial roofs protect high-value assets, people, and production schedules. Yet most failures are not sudden—they are missed early warnings: a loose fastener, a blocked gutter, a hairline crack in a joint. In Pune’s climate, monsoon rainfall and heat cycles accelerate these weaknesses.

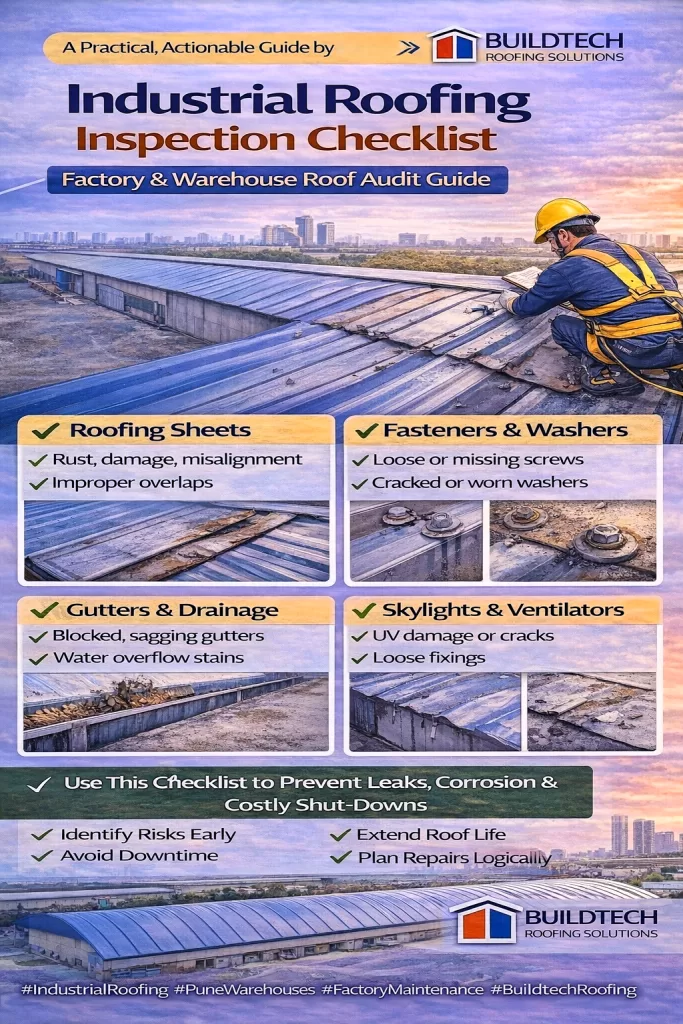

A structured industrial roofing inspection checklist helps facility managers and safety officers identify risks early, plan repairs logically, and avoid emergency shutdowns. This guide explains when to inspect, what to inspect, and how to act on findings—with a clear distinction between DIY checks and professional audits.

When Should Industrial Roofs Be Inspected?

Plan inspections at predictable risk points:

- Pre-monsoon (mandatory): catch issues before heavy rain

- Post-monsoon: assess damage and plan preventive work

- Annual preventive audit: baseline condition and budgeting

- After extreme events: storms, high winds, or hail

Regular timing prevents surprise failures and spreads costs across the year.

Safety Checklist Before Any Roof Inspection

Before stepping onto a roof, ensure safety and compliance.

- PPE: helmet, gloves, non-slip footwear, safety harness

- Fall protection: lifelines, guardrails, anchor points

- Weather check: avoid wet or windy conditions

- Load limits: confirm roof load capacity and access routes

- Access control: restrict unauthorized personnel below

Safety preparation protects inspectors and prevents secondary incidents.

The Industrial Roofing Inspection Checklist (Core)

Use the checklist below section-by-section. Document findings with photos and notes.

✔ 1) Roofing Sheets

Check for:

- Rust spots, coating wear, or pitting

- Cracks, dents, or deformation

- Misalignment or lifted edges

- Improper overlaps

Action: Clean, treat corrosion early, realign sheets, replace damaged sections.

✔ 2) Fasteners, Screws & Washers

Check for:

- Loose or missing fasteners

- Cracked or hardened rubber washers

- Corrosion at screw heads

- Inconsistent spacing

Action: Retighten to specification, replace degraded washers, and standardize spacing.

✔ 3) Joints, Seams & Penetrations

Check for:

- Sealant cracks or gaps

- Watermarks around overlaps

- Leaks near vents, skylights, or cable trays

Action: Reseal joints with industrial-grade sealants; reinforce critical seams.

✔ 4) Gutters & Drainage

Check for:

- Debris accumulation and blockages

- Incorrect slope or sagging sections

- Overflow stains indicating backflow

Action: Clean thoroughly; realign slopes; repair or upsize outlets if needed.

✔ 5) Skylights & Ventilators

Check for:

- UV damage, cracks, or yellowing

- Frame seal integrity

- Loose fixings

Action: Reseal frames; replace damaged panels; secure fixings.

✔ 6) Waterproofing Layers

Check for:

- Peeling, blistering, or cracks

- Weak zones around penetrations

- Old patchwork failures

Action: Repair locally or recoat vulnerable areas before the monsoon.

Metal Roof–Specific Inspection Points

Metal roofs dominate industrial buildings and need focused checks:

- Sheet integrity: thickness wear, edge corrosion

- Thermal movement: allowance gaps intact, no buckling

- Fastener pull-out: signs of movement under wind uplift

- Coating condition: touch-ups where bare metal shows

These checks extend service life beyond 20–30 years.

Industrial Shed & PEB Roof Inspection Points

For sheds and PEB systems, add structural checks:

- Truss alignment and member condition

- Connection plates and bolts

- Signs of differential movement

- Ridge and eave detailing

Structural observations help distinguish surface issues from deeper risks.

Common Issues Typically Found During Inspections

- Early-stage corrosion hidden under overlaps

- Micro-leaks at fasteners and penetrations

- Drainage bottlenecks are causing ponding

- Poor legacy repairs that failed

Identifying these early keeps repairs targeted and affordable.

Interpreting Inspection Results: What to Do Next

| Inspection Result | Recommended Action |

|---|---|

| Minor wear | Preventive maintenance |

| Localized leaks | Targeted repair & resealing |

| Repeated failures | Retrofit or upgrade |

| Structural concerns | Engineering review |

Clear decisions avoid both overspending and risky delays.

DIY Checks vs Professional Roofing Audits

DIY / In-house Checks

- Quick visual scans

- Useful for housekeeping

- Often miss hidden or root-cause issues

Professional Audit

- Systematic checklist

- Photo documentation and reports

- Root-cause analysis and repair prioritization

Professional audits convert observations into an actionable plan.

Documentation: What a Good Inspection Report Includes

- Date, weather, and inspection scope

- Annotated photos of defects

- Severity grading and risk notes

- Repair recommendations with priority

- Maintenance roadmap and budget guidance

Good documentation supports compliance, insurance, and budgeting.

Why Choose Buildtech for Industrial Roof Inspections in Pune

- Industrial-grade checklists tuned to Pune’s climate

- Trained teams with safety compliance

- Photo-rich reports and clear action plans

- Integrated services: inspection → repair → maintenance

Buildtech treats inspections as asset protection, not paperwork.

FAQs: Industrial Roofing Inspection Checklist

How often should industrial roofs be inspected?

At least annually, with mandatory pre-monsoon checks.

Can inspections be done without stopping operations?

Yes. Most audits are planned to avoid disruption.

What areas cause the most leaks?

Joints, fasteners, penetrations, and blocked drainage.

Conclusion: Inspect Early, Fix Smart, Operate Confidently

A disciplined industrial roofing inspection checklist prevents most failures long before they become emergencies. By inspecting at the right times, checking the right details, and acting decisively, factories and warehouses in Pune can avoid downtime, protect assets, and control costs.

For a professional, documented roof audit and a clear maintenance roadmap, Buildtech Roofing Solutions delivers inspections that lead to durable outcomes—not surprises.