Industrial Roofing Annual Maintenance Plan: Prevent Leaks & Reduce Long-Term Costs in Pune

Industrial roofs are constantly exposed to heat, dust, expansion cycles, and heavy monsoon rainfall. In Pune, these environmental stresses gradually weaken roofing systems. However, most failures are not sudden. They begin as small issues—loose fasteners, minor sealant gaps, or blocked gutters.

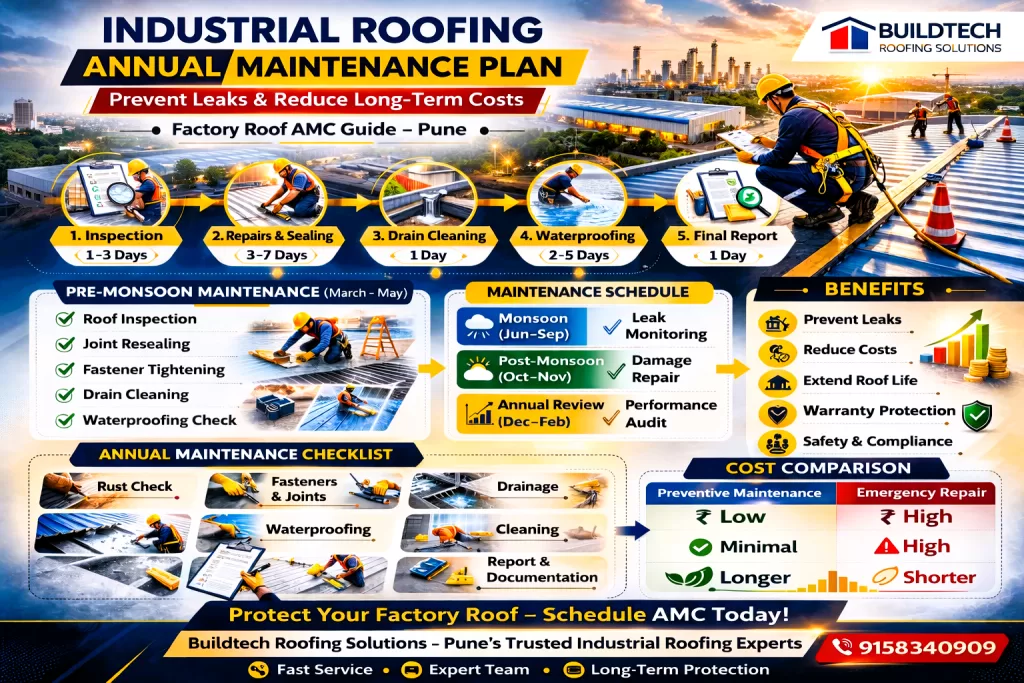

An Industrial Roofing Annual Maintenance Plan prevents these minor defects from turning into expensive operational disruptions. Instead of reacting to leaks, industries can follow a structured preventive strategy that protects assets and stabilises budgets.

Why an Industrial Roofing Annual Maintenance Plan Is Essential

Factories and warehouses depend on roofing systems to safeguard production lines, inventory, and equipment. Without a preventive plan, roofing deterioration accelerates.

A structured Industrial Roofing Annual Maintenance Plan helps:

- Prevent monsoon leakage

- Reduce emergency repair costs

- Extend roof lifespan

- Maintain warranty compliance

- Improve workplace safety

Therefore, maintenance becomes an investment—not an expense.

What Is an Industrial Roofing Annual Maintenance Plan?

An Industrial Roofing Annual Maintenance Plan is a scheduled preventive program designed to keep industrial roofs performing efficiently throughout the year.

Core Components Include:

- Periodic technical inspections

- Fastener tightening and washer replacement

- Joint resealing and waterproofing checks

- Gutter and drainage cleaning

- Corrosion detection and treatment

- Detailed photo documentation

The goal is simple: detect problems early and fix them before they escalate.

Recommended Maintenance Schedule for Pune Industries

Because Pune experiences intense monsoon rainfall, timing is critical.

✅ Pre-Monsoon Inspection (March–May)

This is the most important phase.

- Complete roof inspection

- Joint resealing

- Drainage cleaning

- Fastener tightening

- Waterproofing reinforcement

✅Monsoon Monitoring (June–September)

- Observe drainage performance

- Respond quickly to minor leaks

- Inspect after heavy rainfall events

✅ Post-Monsoon Assessment (October–November)

- Corrosion treatment

- Damage evaluation

- Preventive repairs

✅ Annual Review (December–February)

- Lifecycle evaluation

- Budget planning

- Maintenance performance analysis

Following this schedule ensures year-round protection.

Industrial Roofing Annual Maintenance Checklist

A professional Industrial Roofing Annual Maintenance Plan should include:

Roofing Sheets

- Rust spot detection

- Surface damage inspection

- Alignment checks

Fasteners & Joints

- Replace damaged washers

- Tighten loose screws

- Inspect the sealant condition

Drainage Systems

- Remove debris

- Check downpipe flow

- Test water runoff efficiency

Waterproofing Zones

- Inspect membranes

- Reinforce vulnerable joints

Routine execution prevents recurring issues.

Preventive Maintenance vs Emergency Repairs

| Preventive Maintenance | Emergency Repairs |

|---|---|

| Scheduled & controlled | Sudden & costly |

| Lower annual cost | High unplanned expense |

| Minimal disruption | Production downtime |

| Extended lifespan | Early roof replacement |

Clearly, preventive maintenance delivers stronger financial outcomes.

What Does an AMC Include?

An Annual Maintenance Contract (AMC) under an Industrial Roofing Annual Maintenance Plan typically includes:

- 2–4 scheduled inspections annually

- Preventive minor repairs

- Priority emergency response

- Detailed inspection reports

- Maintenance recommendations

AMC programs create predictable budgeting and faster service support.

Signs Your Facility Needs an Annual Maintenance Plan

You should implement an Industrial Roofing Annual Maintenance Plan if:

- Leaks occur every monsoon

- Repair expenses are increasing

- Roof age exceeds 8–10 years

- Drainage blocks frequently

- Waterproofing patches repeat regularly

These signs indicate that reactive maintenance is already increasing long-term costs.

How an Industrial Roofing Annual Maintenance Plan Extends Lifespan

Consistent maintenance improves durability by:

- Controlling corrosion early

- Maintaining joint integrity

- Preventing water ponding

- Reducing structural stress

With proper care, industrial metal and PEB roofs can exceed their expected service life.

Financial Benefits of a Structured Maintenance Plan

A preventive maintenance strategy provides:

- Lower lifecycle roofing cost

- Reduced downtime

- Delayed replacement investment

- Improved operational stability

- Better compliance documentation

Instead of unpredictable repair bills, roofing becomes a stable infrastructure asset.

Why Choose Buildtech Roofing Solutions in Pune?

Buildtech Roofing Solutions provides:

- Industrial-grade inspection protocols

- Climate-focused preventive planning

- Safety-compliant execution

- Photo-based documentation

- Long-term performance support

This structured approach ensures roofing systems remain durable beyond the warranty period.

FAQs: Industrial Roofing Annual Maintenance Plan

How often should industrial roofs be maintained?

At least once annually, with mandatory pre-monsoon inspection in Pune.

Does maintenance reduce long-term costs?

Yes. Preventive care significantly lowers emergency repair expenses.

Is AMC better than ad-hoc repairs?

Yes. AMC ensures scheduled inspections and priority response.

Does maintenance protect warranty validity?

Yes. Many warranties require documented inspections.

Conclusion

An Industrial Roofing Annual Maintenance Plan transforms roofing from a reactive liability into a controlled, long-term asset. Factories and warehouses in Pune that adopt preventive maintenance experience fewer leaks, lower costs, and extended roof lifespan.

Planned maintenance delivers stability, cost efficiency, and operational confidence year after year.