Metal Deck Sheets for Industrial Construction | Buildtech Roofing Solutions

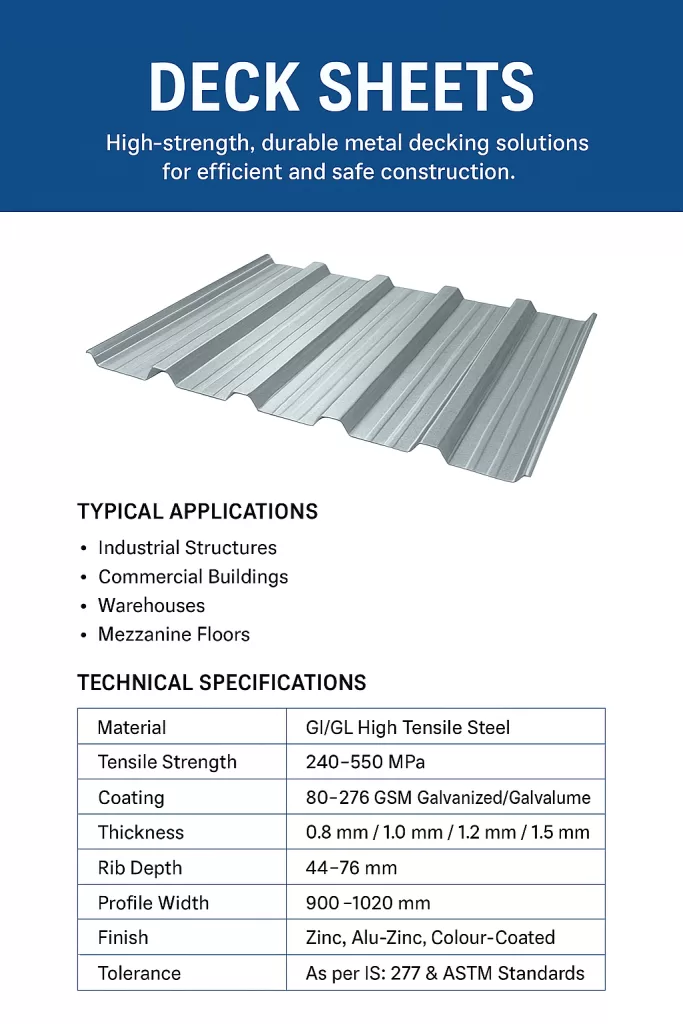

Metal Deck Sheets – Strong, Efficient & Modern Construction Solutions Modern industrial and commercial construction demands faster execution, higher load capacity, and long-term structural reliability. Metal deck sheets meet these requirements by acting as permanent formwork and reinforcement for concrete slabs, thereby improving efficiency and structural performance. At Buildtech Roofing Solutions, we supply and install high-strength metal deck sheets that accelerate construction timelines, reduce overall costs, and deliver dependable performance for industrial projects across India. What Are Metal Deck Sheets? Metal deck sheets are profiled steel sheets used as a base for reinforced concrete slabs or roofing systems. Once concrete is poured, the deck sheet works compositely with concrete, enhancing strength, stiffness, and stability. As a result, the system eliminates the need for conventional shuttering. Types of Metal Deck Sheets 1. Floor Deck Sheets Floor deck sheets are commonly used for RCC slab construction in multi-storey buildings, warehouses, mezzanine floors, and industrial facilities. 2. Roof Deck Sheets Roof deck sheets function as structural roofing systems and can be combined with insulation and waterproofing layers for improved thermal and weather performance. Key Advantages of Metal Deck Sheets ✔ Faster Construction Metal deck sheets remove the need for traditional shuttering, which significantly speeds up slab casting and project completion. ✔ High Load-Bearing Capacity Due to composite action with concrete, metal deck systems deliver superior structural strength. ✔ Cost Savings Reduced shuttering materials, lower labour requirements, and faster timelines help minimise overall construction costs. ✔ Lightweight Structure Metal deck slabs impose a lower dead load compared to conventional RCC slabs. ✔ Durable & Corrosion-Resistant Manufactured using galvanized or colour-coated steel, metal deck sheets offer long-term durability in industrial environments. Applications of Metal Deck Sheets Metal deck sheets are widely used in: Technical Specifications (Typical) Parameter Specification Material GI / PPGI Thickness 0.8 – 1.2 mm Profile Height 50 – 75 mm Span Capability As per the design load Coating Galvanized / Colour-coated Installation Fixed to a steel structure Metal Deck Sheets vs Conventional Slabs Feature Metal Deck Sheets Conventional Slabs Construction Speed Very fast Slow Shuttering Minimal Heavy Load Performance High Moderate Labour Cost Lower Higher Structural Efficiency Excellent Standard Installation Best Practices Buildtech’s experienced installation teams ensure precision, safety, and compliance at every stage. Why Choose Buildtech Roofing Solutions? Conclusion Metal deck sheets are a core solution for modern industrial construction, offering unmatched speed, strength, and cost efficiency. With Buildtech Roofing Solutions, clients receive premium-quality materials and expert execution that meet demanding structural and project requirements.

Metal Deck Sheets for Industrial Construction | Buildtech Roofing Solutions Read More »