Introduction: Why Maintenance Costs Are Predictable — and Far Lower Than Repairs

Industrial roofing failures rarely happen overnight. Problems develop slowly: fasteners loosen, sealants age, gutters clog, and corrosion spreads. When the monsoon arrives, these small issues quickly turn into leaks, water damage, and operational disruptions.

The good news is that industrial roofing maintenance costs in Pune are predictable and manageable when addressed through planned annual programs. Compared to emergency repairs or premature roof replacement, preventive maintenance is significantly more economical.

This guide explains what maintenance includes, how costs vary by roof type, the difference between AMC and ad-hoc spending, and how to budget wisely to protect operations year-round.

What Is Included in Industrial Roofing Maintenance?

Professional roof maintenance is structured and documented — not just a casual visual check.

Typical Maintenance Scope

- Detailed roof inspection (sheets, joints, fasteners, drainage)

- Tightening of fasteners and replacement of damaged washers

- Resealing of joints, overlaps, and penetrations

- Gutter and downpipe cleaning

- Minor corrosion treatment and protective coating touch-ups

- Inspection report with photographs and repair priorities

Result: Early problem detection, reduced leak risk, longer roof lifespan, and predictable annual expenditure.

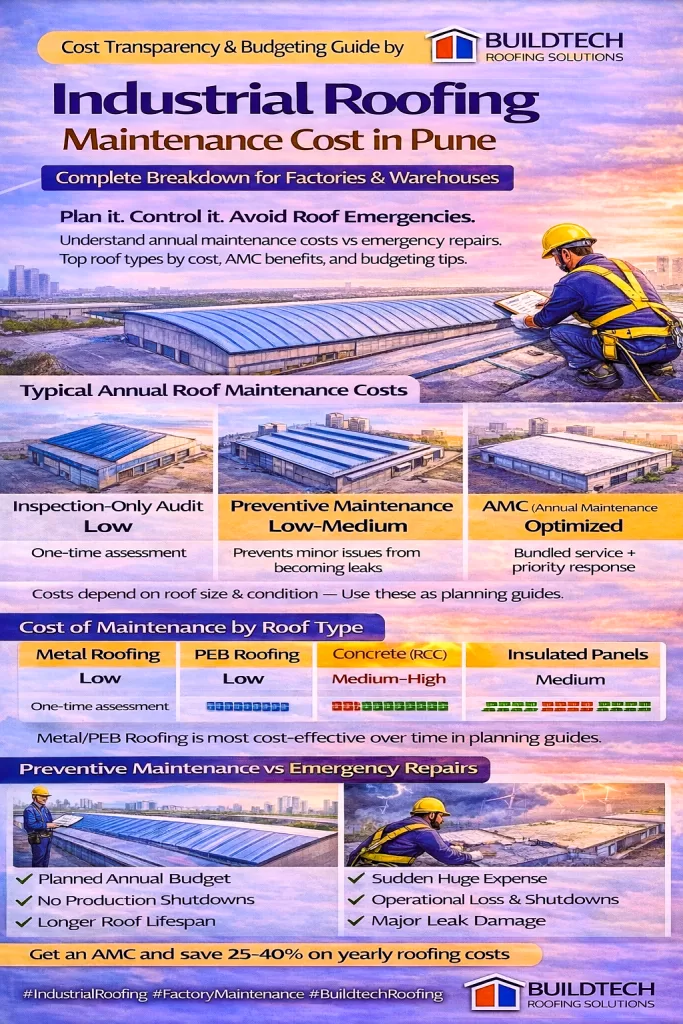

Industrial Roofing Maintenance Cost in Pune (Indicative View)

Maintenance pricing depends on site conditions, roof type, and access requirements. These are planning ranges rather than quotations.

| Service Type | Cost Nature | Purpose |

|---|---|---|

| Inspection-Only Audit | Low, one-time | Condition assessment & planning |

| Preventive Maintenance | Low–Medium annually | Stop small issues from becoming leaks |

| AMC (Annual Maintenance Contract) | Optimized bundled cost | Regular service + priority response |

What Influences Cost?

- Total roof area and height

- Roof age and existing damage

- Number of penetrations (vents, skylights, equipment mounts)

- Drainage complexity

- Safety and access requirements

Maintenance Cost by Roof Type

| Roof Type | Maintenance Frequency | Relative Annual Cost | Key Cost Drivers |

|---|---|---|---|

| Metal Roofing | Low | Low–Medium | Fasteners, joints, coating care |

| PEB Roofing | Low | Low | Engineered detailing, minimal stress points |

| Concrete (RCC) | High | Medium–High | Crack repairs, waterproofing cycles |

| Insulated Panels | Low | Medium | Seal integrity and joint care |

Key Insight: For most Pune factories and warehouses, metal and PEB roofing systems offer the lowest lifecycle maintenance costs.

Preventive Maintenance vs Emergency Repairs

| Preventive Maintenance | Emergency Repairs |

|---|---|

| Planned annual budget | Sudden unplanned expense |

| No production interruption | Possible operational shutdown |

| Minor, controlled repairs | Major leak-related damage |

| Extended roof lifespan | Accelerated deterioration |

A single emergency leak during peak monsoon can cost more than an entire year of preventive maintenance.

Factors That Increase or Reduce Maintenance Costs

Cost-Increasing Factors

- Ageing roofs with no prior maintenance history

- Poor installation practices

- Inefficient drainage systems

- Repeated temporary patchwork

Cost-Reducing Factors

- High-quality roofing materials and fasteners

- Properly engineered slopes and drainage

- Regular pre-monsoon inspections

- Continuous documentation and follow-up

Good design and consistent care directly lower annual maintenance spending.

Why AMC (Annual Maintenance Contracts) Offers Better Value

AMCs transform unpredictable repair costs into a controlled annual plan.

Benefits of an AMC

- Locked annual pricing

- Scheduled inspections (pre-monsoon and mid-cycle)

- Priority response during urgent situations

- Documentation for compliance and insurance

- Predictable budgeting for facility managers

Best suited for: Factories and warehouses where uptime and cost control are critical.

The Hidden Costs of Skipping Maintenance

Delaying maintenance leads to more than just roof damage.

- Recurring leakage and corrosion spread

- Damage to inventory, machinery, and interiors

- Increased safety risks

- Higher insurance claims and compliance concerns

- Premature roof replacement

Skipping maintenance doesn’t eliminate cost — it multiplies it.

Sample Annual Maintenance Budget Structure (Illustrative)

A structured maintenance budget typically includes:

- Annual inspection and reporting

- Two scheduled maintenance visits

- Minor repair allocation

- Contingency allowance for urgent sealing work

This approach ensures the roof remains reliable throughout the monsoon season without unexpected spending spikes.

How to Reduce Maintenance Costs Without Increasing Risk

- Always conduct inspections before the monsoon

- Use industrial-grade sealants and fasteners

- Prioritize drainage efficiency

- Maintain photo-documented service records

- Work with a single specialized roofing partner for consistency

Preventive discipline keeps costs low while preserving roof performance.

Why Choose Buildtech Roofing Solutions for Cost-Effective Maintenance in Pune

- Industrial inspection checklists designed for Pune’s climate

- Safety-trained maintenance teams

- Detailed photo-based reporting

- Integrated services: inspection → repair → maintenance

- Lifecycle-focused approach rather than temporary fixes

Buildtech delivers maintenance strategies that protect assets and reduce long-term roofing costs.

FAQs: Industrial Roofing Maintenance Cost in Pune

How much does industrial roof maintenance cost in Pune?

Costs vary by roof type, size, and condition. Planned maintenance is always more affordable than emergency repairs.

Is an AMC cheaper than ad-hoc repairs?

Yes. AMCs bundle inspections and priority support, reducing total annual expenditure.

How often should maintenance be done?

At least once per year, with a mandatory inspection before the monsoon.

Conclusion: Budget Once, Protect Operations All Year

Understanding industrial roofing maintenance costs in Pune helps factories and warehouses shift from reactive repairs to proactive protection. When maintenance is planned and documented, it becomes a small, predictable annual investment that prevents major financial and operational losses.

Buildtech Roofing Solutions helps industries protect their roofing assets with structured maintenance programs designed for durability, safety, and long-term savings.