The Deck Sheets: Strength, Speed & Safety for Modern Construction

By Buildtech Roofing Solutions

1. Introduction: Why Deck Sheets Matter in Today’s Construction Industry

Construction in India has transformed rapidly—projects now demand faster completion, safer work conditions, and uncompromised structural integrity. Whether it’s an industrial warehouse, commercial complex, metro station, airport terminal, or multi-storey corporate building, Deck Sheets have become one of the most essential components of modern infrastructure development.

At Buildtech Roofing Solutions, we supply engineered deck sheets designed for strength, speed, stability, and sustainability. The cover image for this blog reflects exactly that — a strong metal deck profile supporting modern structures with absolute reliability.

In this guide, you’ll learn:

- What deck sheets are

- Types of deck sheets

- Their advantages

- Technical specifications

- Applications

- Installation guidelines

- Cost and long-term ROI

- Why Buildtech’s deck sheets stand out

Let’s begin.

2. What Are Deck Sheets?

Deck sheets, also called metal decking or floor decking, are high-strength profiled steel sheets that serve as a permanent shuttering base for concrete slabs. Once concrete is poured, the deck sheet acts as a composite structure, increasing slab strength and reducing overall material usage.

Deck Sheets Provide Three Key Functions:

- Structural Support: During construction, they withstand the load from wet concrete and workers.

- Composite Action: After curing, the concrete and deck sheet together create a stronger slab.

- Reinforcement: Ribbed shapes improve bonding with concrete, reducing cracks and deflection.

Buildtech’s deck sheets follow international engineering standards, ensuring long-term performance under varied climate conditions.

3. Types of Deck Sheets Offered by Buildtech Roofing Solutions

a) 44 mm Deck Sheets

- Ideal for medium-load applications

- Strong bonding due to deep ribs

- Suitable for commercial buildings, factories, and mezzanines

b) 76 mm Heavy-Duty Deck Sheets

- Higher load-carrying capacity

- Most preferred for industrial structures, high-rise slabs, airports, and malls

- Supports wide spans

c) Custom-Profile Deck Sheets

- Tailored for project-specific engineering

- Available in multiple thicknesses: 0.8 mm, 1.0 mm, 1.2 mm, 1.5 mm

- Options for galvanised / galvalume coatings

Every profile is designed for superior concrete interlocking, matching global safety standards.

4. Key Advantages of Using Buildtech Deck Sheets

1. Faster Construction

Deck sheets eliminate the need for heavy shuttering and formwork. This reduces labour time and speeds up floor casting by 50–70%.

2. Higher Load-Bearing Strength

The ribbed geometry increases the slab’s bending resistance, allowing architects and engineers to design larger open spaces.

3. Lightweight But Extremely Strong

Steel deck sheets are lightweight, reducing dead load on the structure while improving earthquake resistance.

4. Long-Term Durability

Manufactured using high-tensile galvanised steel, our deck sheets remain rust-free for decades.

5. Reduced Material Usage

Composite slab action means less concrete and less rebar, lowering total project cost.

6. Better Safety

Deck sheets act as a working platform, improving worker safety during construction.

7. Suitable for Any Climate

Whether it’s humid coastal areas or high-temperature industrial zones, deck sheets outperform traditional shuttering.

5. Applications of Deck Sheets

Industrial Projects

- Warehouses

- Factories

- Processing plants

Commercial Buildings

- Shopping malls

- Tech parks

- Showrooms

Infrastructure Projects

- Airports

- Highways

- Metro stations

- Bridges

Residential Construction

- High-rise floors

- Multi-storey apartments

- Mezzanine floors

Special Projects

- Logistics hubs

- Cold-storage buildings

- Power plants

Deck sheets are now preferred across industries due to speed, safety, and superior performance.

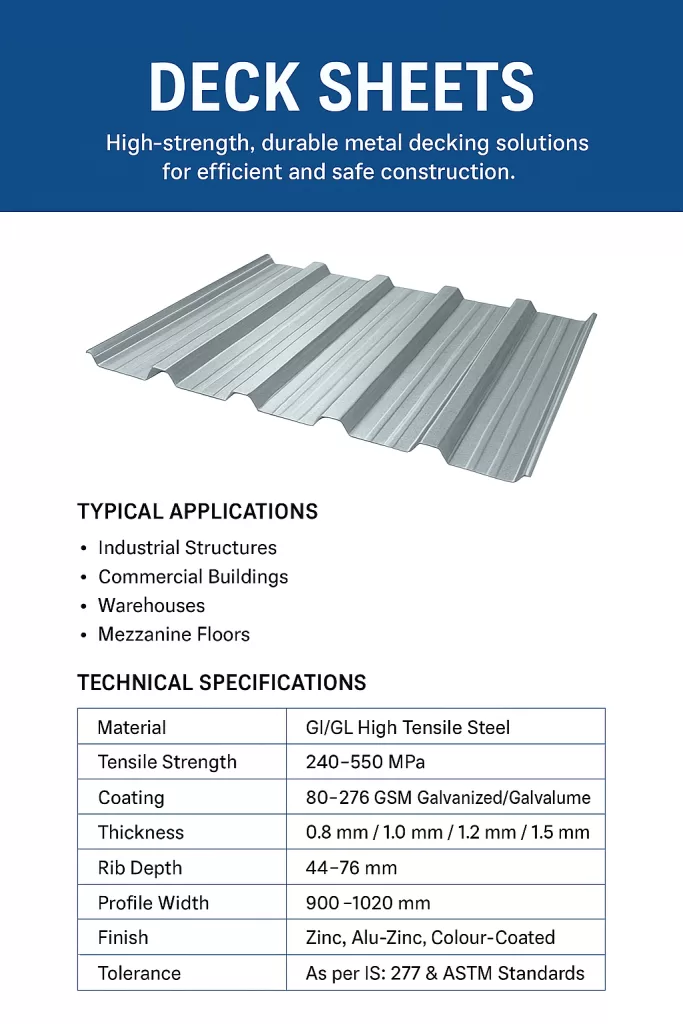

6. Buildtech Deck Sheet Technical Specifications

Below are typical technical parameters (customization available):

| Feature | Specification |

|---|---|

| Material | GI / GL High Tensile Steel |

| Tensile Strength | 240–550 MPa |

| Coating | 80–275 GSM galvanized / galvalume |

| Thickness | 0.8 mm / 1.0 mm / 1.2 mm / 1.5 mm |

| Rib Depth | 44–76 mm |

| Profile Width | 900–1020 mm |

| Finish | Zinc, Alu-Zinc, Colour-Coated |

| Tolerance | As per IS: 277 & ASTM Standards |

7. Installation Process (Step-by-Step)

✔ Step 1 — Layout & Preparation

Check supports, verify alignment, and place sheets in the correct direction.

✔ Step 2 — Fixing the Deck Sheets

Use self-drilling screws or shot-fired fasteners as per engineering load design.

✔ Step 3 — Reinforcement

Place mesh or rebar over the sheets where required.

✔ Step 4 — Concrete Pouring

Concrete is poured evenly to avoid deformation.

✔ Step 5 — Finishing

No formwork removal—deck sheets remain as part of the structure.

This method reduces labour, time, and costs significantly.

8. Why Buildtech Roofing Solutions?

1. High-Quality Materials

Premium GI/GL steel ensures long product life.

2. Precision Engineering

Profiles designed for deep concrete interlocking.

3. On-Time Supply & Fabrication

Large-scale production ensures immediate availability.

4. End-to-End Support

From design to installation, Buildtech supports the complete workflow.

5. Custom Solutions

Thickness, coating, width, and length can all be customized.

6. Intense Quality Testing

Load-bearing, corrosion, adhesion, and bonding tests ensure unmatched reliability.

7. Excellent ROI

Lower maintenance, faster construction, and long life = substantial long-term savings.

9. Frequently Asked Questions

Q1: What is the lifespan of deck sheets?

Buildtech deck sheets last 40–60 years, depending on the environment and coating.

Q2: Are deck sheets fire-resistant?

Yes, in combination with concrete, they create a fire-rated composite slab.

Q3: Do deck sheets reduce project cost?

Yes — reduced shuttering, labour, and reinforcement makes them cost-efficient.

Q4: Can deck sheets be customized?

Absolutely — length, width, rib height, and coating can be customized.

10. Conclusion

Deck sheets have revolutionized industrial and commercial construction. Their strength, speed, safety, and durability make them the new backbone of modern infrastructure.

Buildtech Roofing Solutions is proud to deliver high-performance deck sheets designed for India’s toughest environments.