Product & Services

Our Product & Services

Trust the Experience

METAL BUILDING ACCESERIES by Buildtech Ridge Ventilators

Ridge Ventilator - 300mm, 600mm, 900mm, 1200mm Throat

A ridge vent is a type of vent installed at the peak of a sloped roof that allows warm, humid air to escape a building’s attic. Ridge vents are most common in shingled residential buildings. This vent is installed at the sloped roof which eliminates warm, air from the building’s attic, these ridge vents are manufactured by our proficient professionals utilizing the optimum quality material and advanced technology. Customers can avail of these ridge vents in numerous specifications that can be also be customized as per the requirements of the client. A Ridge ventilator is a type of ventilator installed at the peak of a sloped roof that allows warm, humid air to escape from the building. We provide factory-made (assembled in Factory) and onsite or location assembled a Ridge Ventilator.

METAL BUILDING ACCESERIES by INDUSTRIAL METAL LOUVERS

Metal Louvers

We offer a wide range variety of Industrial Steel, Metal, Aluminium Building Louvers. Whether you require fixed, operable, or vertical storm-proof designs. Aluminum Louvers, Metal Louvers, Steel Louver, Weather Louvers, Gravity Air Louver & Ventilation Louvers, Exhaust Fan Louvre there same type of Louvers list. Our organization has successfully expanded its business in the market owing to the offered elevated quality array of Aluminium Louvers. Our offered aluminum louver is precisely designed by our experienced professionals using high-quality material keeping in mind the defined industry standards. This aluminum louver is properly checked in terms of quality from our side before dispatching to customers. We also provide this aluminum louver to our customers within the stipulated time frame.

METAL DECK SHEET by Metal Deck Sheet

Metal Deck Sheet

Ideal Decking Sheets for Power Plant, Industrial Building & Commercial High rise Buildings. Easy Installation, Cost Saving, Long Lasting.

Manufactured By Buildtech Roofing Solutions. Structures that are similar to pergolas but have fixed roofs may be referred to as pavilions or gazebos. A pavilion is a freestanding structure with a solid roof but no walls to block the fresh air. It provides a sheltered space for people to gather while they enjoy an unfettered view of the outdoors. Decking Sheets are flat surfaces or platforms capable of supporting flooring and roofing sheets and these are connected to the outer or inner part of the building structure. These sheets are very helpful in reducing the concentrated loading effect of roofing on the building structures by proper distribution of load.

Onduline About Onduline Roofing Systems Company

ONDULINE ROOFING SYSTEMS

The Onduline is a lightweight roofing solution ideal for both houses and outbuildings. It features a unique technology that combines cellulosic fibers and selected bitumen for better waterproofing performance. Homeowners appreciate ONDULINE ROOFING SYSTEMS for their multiple advantages:

- Bitumen sheets and associated roofing accessories are extremely lightweight, making them fast and easy to install.

- An Onduline is guaranteed for its waterproofing performance. Onduline roofs are proven to withstand strong winds (up to 260 km/h).

- In warm weather, the material helps to maintain a comfortable temperature inside the building, while composite fibers aid noise reduction, especially during heavy rain.

- Onduline corrugated bitumen sheets and associated accessories are also 100% eco-friendly.

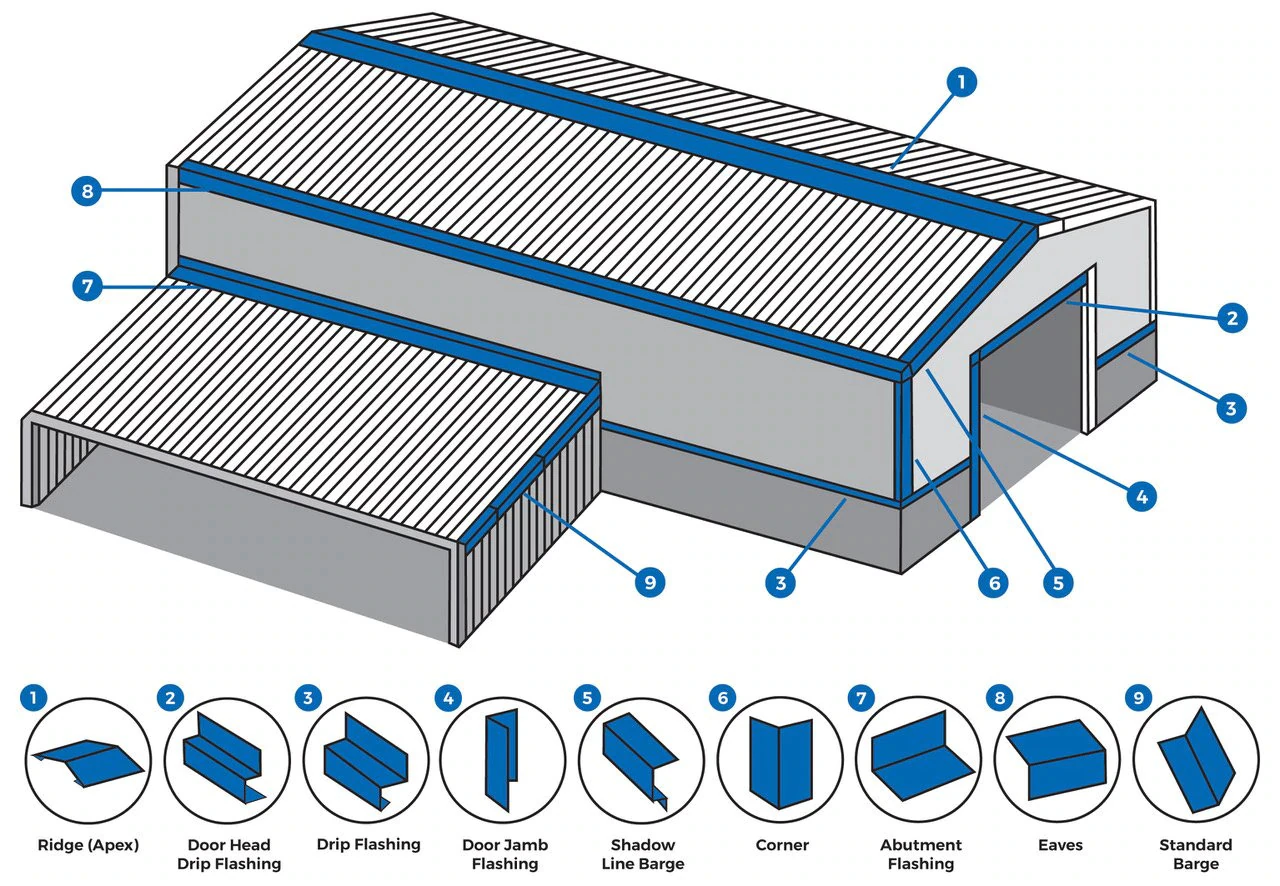

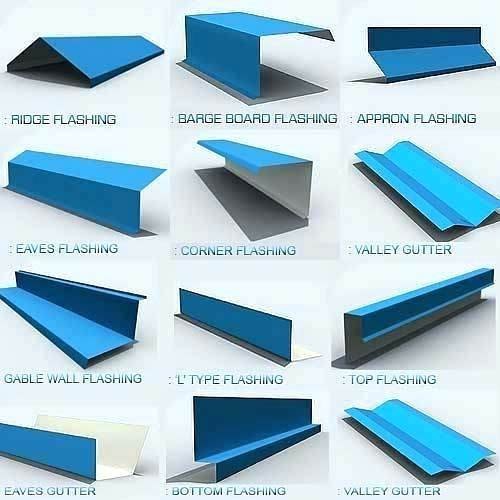

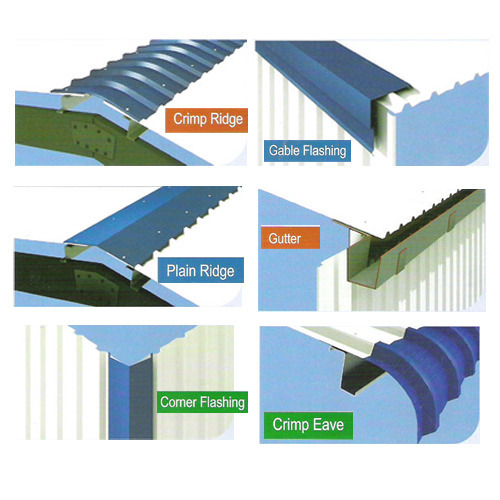

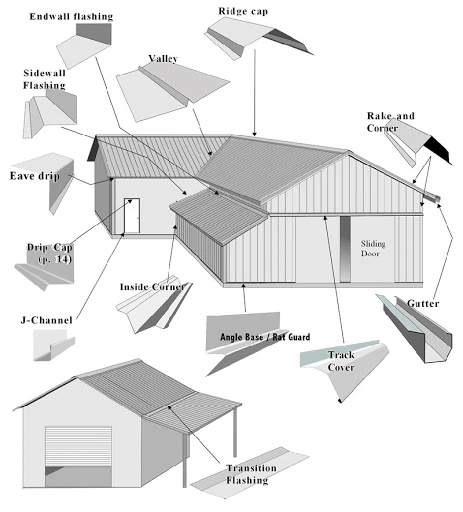

METAL BUILDING ACCESERIES by Metal Flashing

Metal Flashing

In modern buildings, flashing is intended to decrease water penetration at objects such as chimneys, vent pipes, walls, windows, and door openings to make buildings more durable and to reduce indoor mold problems. Metal flashing materials include lead, aluminum, copper, stainless steel, zinc alloy, and other materials. Buildtech metal roof and wall accessories add value to any metal building project. Our products, including clips, coils, flat sheets, windows, sealants, insulation, and more, are manufactured using the highest-quality materials to ensure the integrity and longevity of your structure.

METAL BUILDING ACCESERIES by Air Turbo ventilation

Air Turbo Ventilation

Air turbo ventilation, also known as wind turbine ventilation or roof turbine vents, is a type of passive ventilation system used to improve indoor air quality and regulate temperature within a building. These ventilation products utilize the natural force of wind to create a flow of air that helps exhaust hot and stale air from the interior space.

Here’s some information about air turbo ventilation products:

How Air Turbo Ventilation Works:

Air turbo ventilation systems consist of a turbine-like device installed on the roof. The device contains a series of vanes or blades that spin when exposed to wind. As the wind blows, it creates a pressure difference between the interior and exterior of the building. This pressure difference causes air to be drawn out from the interior space through the vents. Simultaneously, fresh air is drawn in through openings or vents located at lower levels of the building, creating a natural cycle of air exchange.

Benefits of Air Turbo Ventilation:

- Energy Efficiency: Air turbo ventilation operates without the need for electricity or mechanical components, making it an energy-efficient solution for ventilating spaces.

- Improved Indoor Air Quality: The constant air exchange helps remove pollutants, odors, and moisture from the indoor environment, contributing to better air quality.

- Temperature Regulation: By expelling hot air from the building’s upper areas, air turbo ventilation helps regulate indoor temperatures, especially in warmer seasons.

- Reduction in Condensation: Adequate ventilation minimizes the risk of condensation buildup, which can lead to mold and mildew growth.

- Cost Savings: Since it operates passively, air turbo ventilation systems don’t rely on ongoing electricity usage, resulting in potential cost savings over time.

- Low Maintenance: These systems have relatively low maintenance requirements due to their simple design.

Considerations and Installation:

- Air turbo ventilation systems are most effective in areas with consistent wind patterns.

- Proper installation is essential to ensure optimal performance. The vent should be positioned on the roof’s highest point to maximize the wind’s impact.

- Maintenance might involve periodic cleaning of the blades to remove dust or debris that could hinder their movement.

- Some modern designs include bearings or lubrication to reduce friction and allow the turbine to spin even with minimal wind.

When considering the installation of an air turbo ventilation system, it’s advisable to consult with professionals who specialize in ventilation solutions to determine if this type of system is suitable for your specific building and climate conditions.

METAL BUILDING ACCESERIES by Gutters Downtake Pipe

Colour Coated Gutters /GI Gutter

Color coated gutters and galvanized iron (GI) gutters are essential components of a building’s roofing and drainage system. They play a crucial role in diverting rainwater away from the building’s foundation, preventing water damage, erosion, and other structural issues. Here’s some information about both types of gutters:

Color Coated Gutters:

Color coated gutters, also known as pre-painted gutters, are metal gutters that have been coated with a layer of paint or protective coating. This coating serves both functional and aesthetic purposes. Here’s an overview:

Materials: Color coated gutters are typically made from materials like galvanized steel, aluminum, or stainless steel. These materials offer durability and resistance to corrosion.

Benefits:

- Aesthetics: The color coating adds an attractive finish to the gutters, allowing them to blend seamlessly with the building’s exterior.

- Corrosion Resistance: The coating provides an extra layer of protection against rust and corrosion, extending the gutters’ lifespan.

- Low Maintenance: Color coated gutters require less maintenance compared to unpainted gutters, as the coating helps resist dirt and environmental elements.

- Customization: These gutters are available in a range of colors, allowing homeowners to choose a shade that complements their building’s design.

Galvanized Iron (GI) Gutters:

GI gutters are made from galvanized iron, which is iron that has been coated with a layer of zinc to protect it from corrosion. GI gutters are known for their durability and strength. Here’s an overview:

Materials: Galvanized iron gutters are made from iron that has been coated with a layer of zinc through a process called galvanization.

Benefits:

- Corrosion Resistance: The zinc coating provides excellent resistance against rust and corrosion, making GI gutters suitable for various weather conditions.

- Strength: GI gutters are robust and can withstand heavy rainfall, snow, and other external pressures.

- Longevity: Properly maintained GI gutters can last for many years, making them a cost-effective choice in the long run.

- Cost-Effective: GI gutters are relatively affordable, making them a popular choice for many residential and commercial buildings.

Installation and Maintenance:

Both color coated and GI gutters should be installed by professionals to ensure proper drainage and minimize the risk of leaks. Regular maintenance involves cleaning debris and leaves from the gutters to prevent clogs and water overflow.

When choosing between color coated and GI gutters, consider factors such as your building’s aesthetic requirements, budget, climate conditions, and the level of maintenance you’re willing to undertake. Consulting with roofing and gutter experts can help you make an informed decision based on your specific needs.

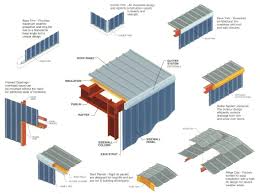

METAL BUILDING ACCESERIES by Metal Building Accessories

Metal Building Accessories

At Heritage, we offer quality and cost-effective steel building accessories for complete customization of your building

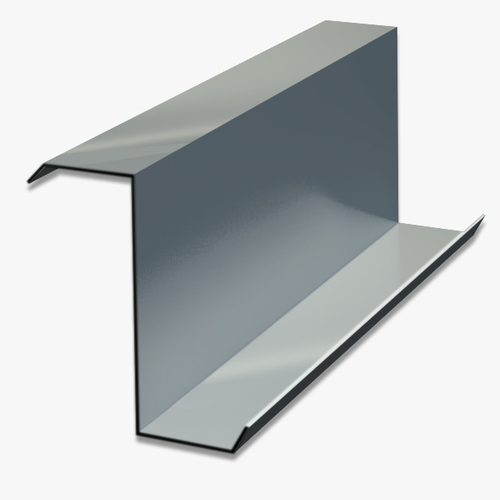

METAL BUILDING MANUFACTURING by by Z Type Purlin

Z Type Purlin

Z-purlins are structural components commonly used in metal building construction to provide support for roofing and cladding systems. They are shaped like the letter “”Z”” and are often used as secondary framing elements to attach roof and wall panels to the primary structural framework. Here’s an overview of Z-type purlins:

Functions and Uses:

Secondary Structural Support: Z-purlins are typically installed perpendicular to the primary steel framing members, such as rafters or columns. They provide support for roof and wall panels, transferring the loads from the panels to the primary framework.

Attachment Points: Z-purlins serve as attachment points for roof and wall panels. These panels can be fastened directly to the purlins, creating a secure and stable surface for the building envelope.

Z-purlins are structural components commonly used in m

Spacing and Layout: The spacing and layout of Z-purlins depend on factors such as the building’s span, load requirements, and local building codes. Proper spacing ensures even weight distribution and structural integrity.

Advantages:

Cost-Efficiency: Z-purlins are cost-effective compared to traditional timber framing due to their efficient manufacturing process and material usage.

Lightweight and Strong: Cold-formed steel used in Z-purlins is lightweight while maintaining strength, making them suitable for a wide range of building applications.

Quick Installation: Z-purlins are designed for easy installation, reducing construction time.

Compatibility: They are compatible with various roofing and cladding materials, allowing for flexibility in design.

Installation and Considerations:

- Z-purlins should be installed according to manufacturer guidelines and engineering specifications to ensure proper load distribution and structural integrity.

- It’s important to consider factors such as wind loads, snow loads, and any additional loads that the roof and wall panels will experience.

- Proper fasteners, such as self-drilling screws, should be used to secure the roof and wall panels to the purlins.

- Consulting with structural engineers or professionals experienced in metal building construction is recommended to determine the appropriate size and spacing of Z-purlins for your specific project.

Z-purlins play a crucial role in ensuring the stability and longevity of metal buildings, providing the necessary support for roofing and cladding systems while maintaining cost-efficiency and ease of installation.”

etal building construction to provide support for roofing and cladding systems. They are shaped like the letter “”Z”” and are often used as secondary framing elements to attach roof and wall panels to the primary structural framework. Here’s an overview of Z-type purlins:

Functions and Uses:

Secondary Structural Support: Z-purlins are typically installed perpendicular to the primary steel framing members, such as rafters or columns. They provide support for roof and wall panels, transferring the loads from the panels to the primary framework.

Attachment Points: Z-purlins serve as attachment points for roof and wall panels. These panels can be fastened directly to the purlins, creating a secure and stable surface for the building envelope.

METAL BUILDING MANUFACTURING by C Type Purlin

C Type Purlin

C-purlins, also known as channel purlins, are structural components commonly used in metal building construction to provide support for roofing and cladding systems. They are shaped like the letter “”C”” and are utilized as secondary framing elements. Here’s an overview of C-type purlins:

Functions and Uses:

- Secondary Structural Support: C-purlins are typically installed horizontally, parallel to the primary steel framing members, such as rafters or trusses. They provide support for roof and wall panels and help transfer the loads from the panels to the primary framework.

- Attachment Points: Roof and wall panels can be attached directly to the top flange of the C-purlins, providing a secure surface for the building envelope.

- Spacing and Layout: The spacing and layout of C-purlins depend on factors such as the span of the building, load requirements, and local building codes. Proper spacing ensures even weight distribution and structural integrity.

Advantages:

- Strength and Durability: Cold-formed steel used in C-purlins provides strength and durability while maintaining a relatively lightweight profile.

- Cost-Effective: C-purlins are cost-effective due to their efficient manufacturing process and the lightweight properties of cold-formed steel.

- Quick Installation: C-purlins are designed for easy installation, contributing to reduced construction time.

- Versatility: They are compatible with various roofing and cladding materials, allowing for design flexibility.

Installation and Considerations:

- Proper installation of C-purlins is essential to ensure load distribution and structural stability. Manufacturer guidelines and engineering specifications should be followed.

- Consideration should be given to factors like wind loads, snow loads, and any additional loads the roof and wall panels will experience.

- Adequate fasteners, such as self-drilling screws, should be used to attach the roof and wall panels to the purlins.

- Consulting with structural engineers or professionals experienced in metal building construction is recommended to determine the appropriate size and spacing of C-purlins for your specific project.

In metal building construction, C-purlins play a crucial role in providing support for roofing and cladding systems. They contribute to the overall stability and longevity of the building while offering cost-efficiency and ease of installation.”

METAL BUILDING SHEET by klip lok roof sheeting

Klip Lok Roof Sheets

Klip Lok roof sheets are a type of roofing material commonly used in metal building construction. They are known for their durability, weather resistance, and ease of installation. Klip Lok is a proprietary name for a specific type of roofing profile that is designed for efficient and secure interlocking installation. Here’s an overview of Klip Lok roof sheets:

Profile and Design:

Klip Lok roof sheets have a unique profile characterized by raised ribs and a concealed fastening system. The ribs provide structural strength while the concealed clips and fasteners give the roof a clean and sleek appearance.

Installation and Considerations:

- Klip Lok roof sheets are installed using a specialized clip and fastener system that is designed to securely interlock the sheets.

- Proper installation techniques, including sealing and flashing, are crucial to ensure water-tightness and long-term performance.

- Consult the manufacturer’s guidelines and recommendations for installation, including the appropriate clip spacing and fastener requirements.

- Depending on the specific profile and material, Klip Lok roof sheets can be suitable for both residential and commercial applications.

Maintenance:

Routine maintenance for Klip Lok roof sheets involves regular cleaning to remove debris, dirt, and potential contaminants that could affect the appearance and performance of the roofing.

When considering Klip Lok roof sheets for your project, it’s important to work with professionals experienced in metal roofing installation to ensure proper installation, sealing, and weatherproofing. The specific details, materials, and installation methods may vary based on the manufacturer and the design of the profile.

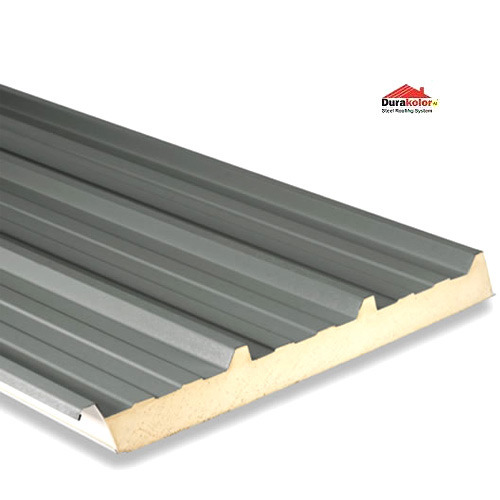

METAL BUILDING SHEET by Insulated LEP metal Sheet

PUF Insulated Panels

Insulated PUF (Polyurethane Foam) metal sheets, also known as PUF insulated panels or PUF sandwich panels, are a type of building material commonly used in construction for their excellent thermal insulation properties and ease of installation. These panels consist of a rigid foam core sandwiched between two metal sheets, creating a lightweight and energy-efficient building envelope. Here’s an overview of insulated PUF metal sheets:

Composition:

Insulated PUF metal sheets consist of the following layers:

- Outer Metal Sheets: Typically made from steel or aluminum, these sheets provide structural support and protection against external elements.

- Polyurethane Foam Core: The foam core provides thermal insulation, minimizing heat transfer and maintaining comfortable indoor temperatures.

- Adhesive: A specialized adhesive binds the foam core to the metal sheets, ensuring a secure and durable panel.

Installation and Considerations:

- Insulated PUF metal sheets can be installed vertically or horizontally on the building’s framework.

- Proper installation is crucial to ensure that panels are securely fastened, and seams are properly sealed to maintain the panels’ insulating properties.

- Insulated panels should be properly supported and installed according to manufacturer guidelines and engineering specifications.

- Panels should be installed with proper flashing and sealing to prevent water infiltration and maintain the building envelope’s integrity.

Maintenance:

Routine maintenance involves inspecting the panels for any signs of damage, ensuring that the seams and fasteners are intact, and addressing any issues promptly to maintain the insulation’s effectiveness.

When considering the use of insulated PUF metal sheets, it’s recommended to consult with professionals experienced in their installation to ensure proper installation, sealing, and weatherproofing. The specific details and materials may vary based on the manufacturer and the application.

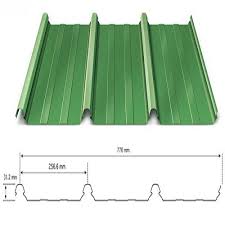

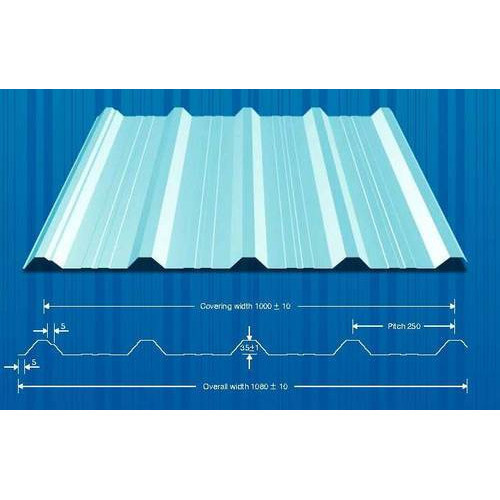

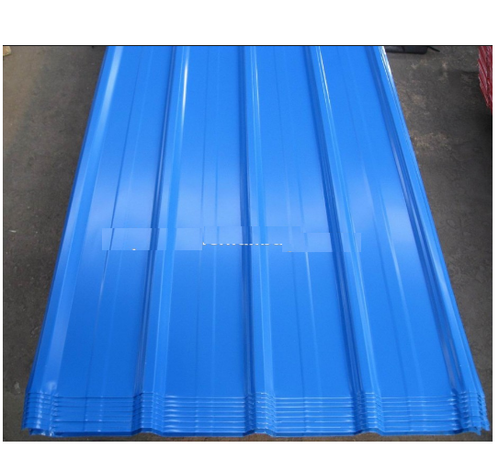

ROOFING AND WALL CLADDING by Trapozaidal Roofing sheet

Trapozaidal Roofing Sheet

Trapezoidal roofing sheets, also known as corrugated roofing sheets or simply trapezoidal sheets, are a popular roofing material commonly used in industrial, commercial, and residential construction. They are named after their distinctive trapezoidal or corrugated profile, which provides structural strength and efficient water runoff. Here’s an overview of trapezoidal roofing sheets:

Profile and Design:

Trapezoidal roofing sheets have a series of parallel ridges and valleys that create a corrugated or trapezoidal pattern when viewed from the side. This profile is designed to enhance the sheet’s strength, water-shedding capability, and load-bearing capacity.

Materials:

Trapezoidal roofing sheets are typically made from various materials, including:

Galvanized Steel: Coated with a layer of zinc for corrosion resistance.

Zincalume: A combination of zinc and aluminum for enhanced durability.

Color-Coated Steel: Steel sheets coated with a layer of paint or protective finish for aesthetics and added protection.

Installation and Considerations:

Trapezoidal sheets are installed by overlapping and fastening them to the roof structure using screws or other appropriate fasteners.

Proper installation is crucial to ensure that the sheets are securely attached, the seams are properly sealed, and flashing is applied where necessary.

The roof’s pitch and design will influence the sheet’s orientation and installation method.

Manufacturer guidelines and engineering specifications should be followed to ensure structural integrity and waterproofing.

Maintenance:

Routine maintenance involves inspecting the sheets for any signs of damage, ensuring that fasteners are secure, and addressing any issues promptly to prevent water infiltration.

Trapezoidal roofing sheets offer a combination of durability, strength, and water-shedding capabilities, making them a popular choice for a variety of building applications. It’s important to consult with roofing professionals experienced in installation and maintenance to ensure proper roofing system performance.

Roof Inspection Services

Scheduling An Appointment

Contact us today to schedule a comprehensive roof inspection. We'll ensure your roof remains in top-notch condition for years to come.